|

|

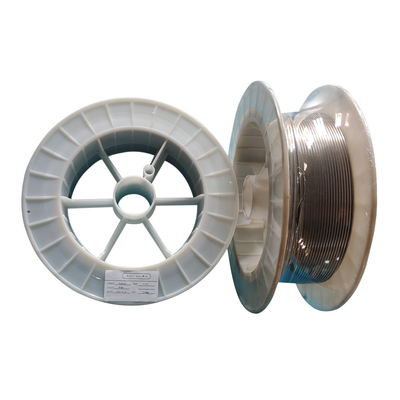

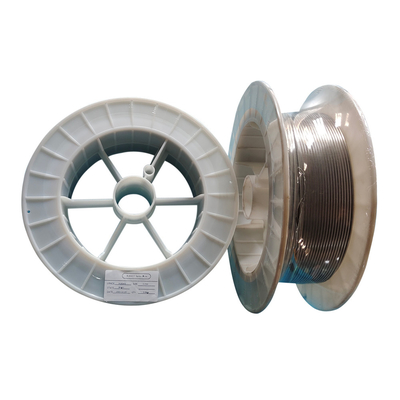

Hastelloy C276 TIG MIG Welding Wire, AWS A5.14 ERNiCrMo-4, UNS 2.4819, for Corrosion Resistance

|

|

제품 상세 정보:

결제 및 배송 조건:

|

상세 제품 설명

| 재료: | 하스텔로이 C-276 | 지름: | 1.6mm, 2.0mm |

|---|---|---|---|

| 패키지: | 15 킬로그램 /는 감깁니다 | 애플리케이션: | 열 용사 피막 |

| 분무 방식: | 아크 용사 | 본드 강도: | 10000 psi |

| 부착율: | 70% | ||

| 강조하다: | Hastelloy C276 welding wire,ERNiCrMo-4 TIG MIG wire,corrosion resistant thermal spray wire |

||

Hastelloy C276 TIG MIG Welding Wire, AWS A5.14 ERNiCrMo-4, UNS 2.4819, for Corrosion Resistance

| Product | Chemical Composition | Available Sizes | Comparable Products | Hardness and Bond Strength | Typical Characteristics and Applications |

| Name | |||||

| Inconel 625 | Nickel Chrome | 1.6mm, 2.0mm | Tafa 71T | 92 Rb | Caustic stress corrosion |

| Molybdenum | Metco 8625 | 6970 PSI | Restoration of worn or mismachined components | ||

| Ni 22Cr 10Mo 2Fe | |||||

| Inconel® 625 | |||||

| C-276 | Nickel Chrome | 1.6mm, 2.0mm | Tafa 77T | 35 Rc | Acidic and hot gas corrosion |

| Molybdenum | 6990 PSI | Good abrasion and metal-to- metal wear | |||

| Ni 20Cr 20Mo 7Fe 4W | |||||

| Hastelloy C-276 | |||||

| Inconel 718 | Nickel Chrome | 1.6mm, 2.0mm | Tafa 78T | 30 Rc | Acidic and hot gas corrosion |

| Molybdenum | Metco 8718 | 8992 PSI | Restoration of worn or mismachined components | ||

| Ni 18.5Cr 18.5Fe 3.0Mo | |||||

| Inconel® 718 | |||||

| SS 316 | Stainless Steel | 1.6mm, 2.0mm | Tafa 85T | 93-97 Rb | Corrosion protection |

| 316 S.S. | Metco Metcoloy 4 | 4100 PSI | Dimensional restoration | ||

| OCr25Al5 | Iron Chrome | 1.6mm, 2.0mm | Tafa 24CA | 88 Rb | Boiler applications |

| Aluminum | Praxair ALCRO | 7770 PSI | Excellent machinability | ||

| Fe 23.5Cr 5.3Al .65Si | Ability to have featheredge coatings |

![]()

![]()

FAQ

연락처 세부 사항

Ohmalloy Material Co.,Ltd

담당자: Mr. Qiu

전화 번호: +8613795230939

회사에 직접 문의 보내기